Crane Servicing

- Regular Inspections:We conduct periodic inspections to ensure your crane operates smoothly and safely.

- Lubrication & Adjustments:Regular lubrication and adjustment of moving parts to prevent wear and tear.

- Component Cleaning:Cleaning of crane components to remove debris and prevent contamination that could affect performance.

- Operational Testing:We perform load and motion tests to ensure your crane meets operational standards.

Crane Repair Service

- Emergency Repairs:Quick response and efficient repair services to minimize downtime.

- Replacement of Damaged Parts:We provide genuine spare parts for replacing any damaged components.

- Structural Repairs:Repair of crane structures, including beams, supports, and joints.

- Electrical System Repairs:Troubleshooting and fixing electrical issues to ensure safe crane operation.

Crane Maintenance Services

- Preventive Maintenance:Regular checks and service to prevent potential issues before they arise.

- Predictive Maintenance:Utilizing data to predict when maintenance should be performed, reducing the likelihood of unexpected failures.

- Condition-Based Maintenance:Maintenance is performed based on the actual condition of the equipment rather than a set schedule.

- Comprehensive Reporting:Detailed maintenance reports are provided, documenting the condition of the crane and any actions taken.

Crane Maintenance Services

- Preventive Maintenance:Regular checks and service to prevent potential issues before they arise.

- Predictive Maintenance:Utilizing data to predict when maintenance should be performed, reducing the likelihood of unexpected failures.

- Condition-Based Maintenance:Maintenance is performed based on the actual condition of the equipment rather than a set schedule.

- Comprehensive Reporting:Detailed maintenance reports are provided, documenting the condition of the crane and any actions taken.

EOT Cranes Overhauling

- Complete Disassembly:Overhaul begins with a complete disassembly of the crane to inspect all components.

- Component Refurbishment:Reconditioning of worn or damaged components to restore them to like-new condition.

- System Upgrades:Integration of modern technologies to enhance crane performance and extend its service life.

- Reassembly and Testing:After overhauling, the crane is reassembled and tested to ensure optimal performance.

Crane Health Checkup

- Detailed Inspections:In-depth examination of all crane components, including mechanical, structural, and electrical systems.

- Performance Analysis:Assessing crane performance under different loads and conditions.

- Risk Assessment:Identifying potential risks and recommending solutions to mitigate them.

- Health Report:A comprehensive report detailing the crane’s health and any recommended actions.

Modification and Relocation

- Design Modifications:Tailoring your crane to meet changing operational needs, including capacity upgrades and modifications.

- Relocation Planning:Strategic planning for the safe and efficient relocation of cranes to new sites.

- Dismantling & Reassembly:Professional dismantling, transportation, and reassembly of cranes at the new location.

- Operational Testing Post-Relocation:Ensuring the crane functions correctly after relocation.

Modernisation and Upgradation

- Technology Integration:Incorporating the latest technology to improve crane control and performance.

- Efficiency Improvements:Upgrading mechanical and electrical components to enhance operational efficiency.

- Safety Enhancements:Implementing advanced safety features to protect workers and equipment.

- Customization:Tailoring modernization efforts to meet specific operational requirements.

Erection and Commissioning

- Foundation and Assembly:Laying a strong foundation and assembling the crane to meet technical specifications.

- Alignment and Calibration:Precise alignment and calibration of crane components to ensure smooth operation.

- Load Testing:Performing load tests to verify the crane’s capacity and safety.

- Commissioning:Final checks and commissioning to ensure the crane is ready for operation

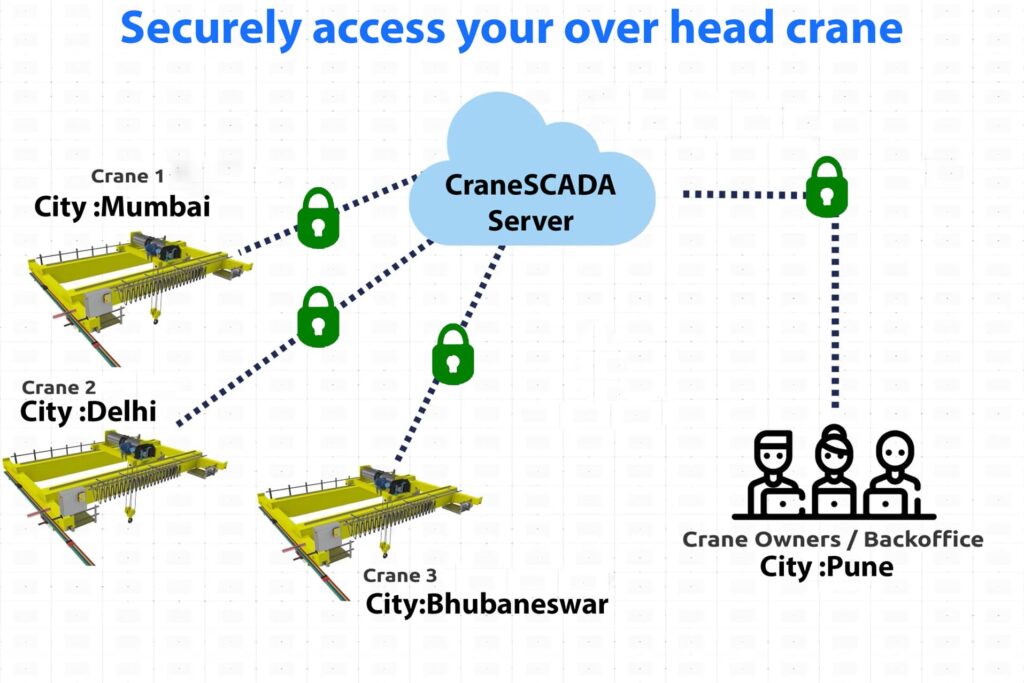

Remote Crane Monitoring

- Real-Time Data Collection:Gathering real-time data on crane performance and operating conditions.

- Remote Diagnostics:Identifying issues and potential failures remotely, allowing for proactive maintenance.

- Performance Alerts:Alerts for critical issues, enabling quick response to prevent downtime.

- Maintenance Scheduling:Automated scheduling of maintenance activities based on data analysis.

Repair Service

- Minor Repairs:Quick fixes for minor issues that could disrupt crane operations.

- Major Overhauls:Extensive repairs to restore severely damaged or worn cranes to full functionality.

- On-Site & Off-Site Repairs:Whether on-site at your facility or at our service center, we offer comprehensive repair solutions.

- Warranty Repairs:Repairs covered under warranty terms, ensuring your investment is protected.

Annual Maintenance Contract (AMC)

- Customized AMC Plans:Tailored AMC packages that fit your operational needs and budget.

- Regular Maintenance Visits:Scheduled maintenance visits throughout the year to keep your crane in top condition.

- Priority Service:AMC customers receive priority service, ensuring minimal disruption to operations.

- Comprehensive Coverage:AMCs cover all aspects of crane maintenance, from inspections and repairs to parts replacement.